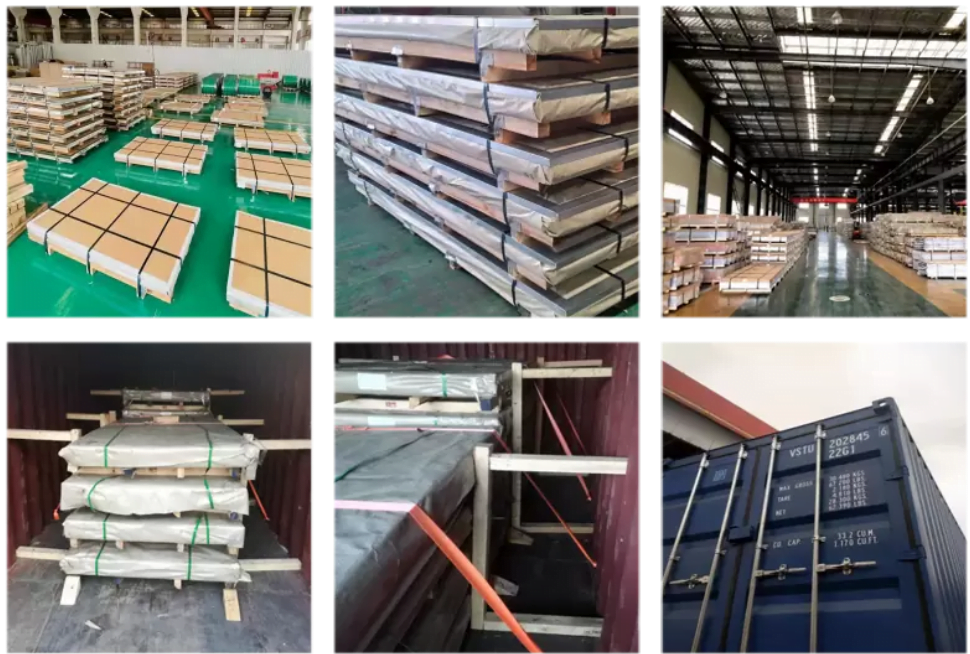

Our group mainly produces galvanized steel coil / aluminized zinc coil. At present, it can produce 10-500g / m ², There are 6 galvanizing production lines with a daily output of more than 1000 tons, mainly including, PPGI, PPGL, dx51d, and dx52d. There are thousands of tons of galvanized steel coils in stock, and the delivery time is guaranteed. At present, the main customer base is concentrated in South Africa, Central Asia, and Europe, with thousands of tons of inventory to meet customer needs.

![]() Whatsapp : +8613964179367

Whatsapp : +8613964179367

![]() E-mail: sales@ruixiangsteelgroup.com

E-mail: sales@ruixiangsteelgroup.com